| 起订: | 供货总量: |

| 发货期限: 自买家付款之日起 天内发货 | 所在地: 陕西 西安市 |

| 有效期至: 长期有效 | 品牌:西安林亚选材 |

详情介绍

灌浆料 高强 微膨胀 流动性好The grouting material has high strength, slight expansion and good fluidity

一、灌浆料产品介绍Introduction to Grouting Material products:

灌浆料以特种水泥作为结合剂,特选高强度材料为骨料,辅以高流态,微膨胀,防离析等物质配制而成。该产品具有自流性好,快硬、早强、高强、无收缩、微膨胀;无毒、无害、不老化、对水质及周围环境无污染,自密性好、防锈等特点。在施工方面具有质量可靠,降低成本,缩短工期和使用方便等优点。从根本上改变设备底座受力情况,使之均匀地承受设备的全部荷载,从而满足各种机械,电器设备(重型设备高精度磨床)的安装要求,是无垫安装时代的理想灌浆材料Grouting material is formulated with special cement as the binder, specially selected high-strength materials as aggregates, and supplemented with substances such as high fluidity, micro-expansion, and anti-segregation. This product features excellent self-flowing property, fast hardening, early strength, high strength, no shrinkage and slight expansion. It is non-toxic, harmless, does not age, causes no pollution to water quality and the surrounding environment, has good self-sealing properties and is rust-proof. It has the advantages of reliable quality, cost reduction, shortened construction period and convenient use in construction. It fundamentally changes the force condition of the equipment base, enabling it to evenly bear the entire load of the equipment, thereby meeting the installation requirements of various mechanical and electrical equipment (heavy equipment, high-precision grinders), and is an ideal grouting material in the era of padless installation.。二、适用范围Scope of application:

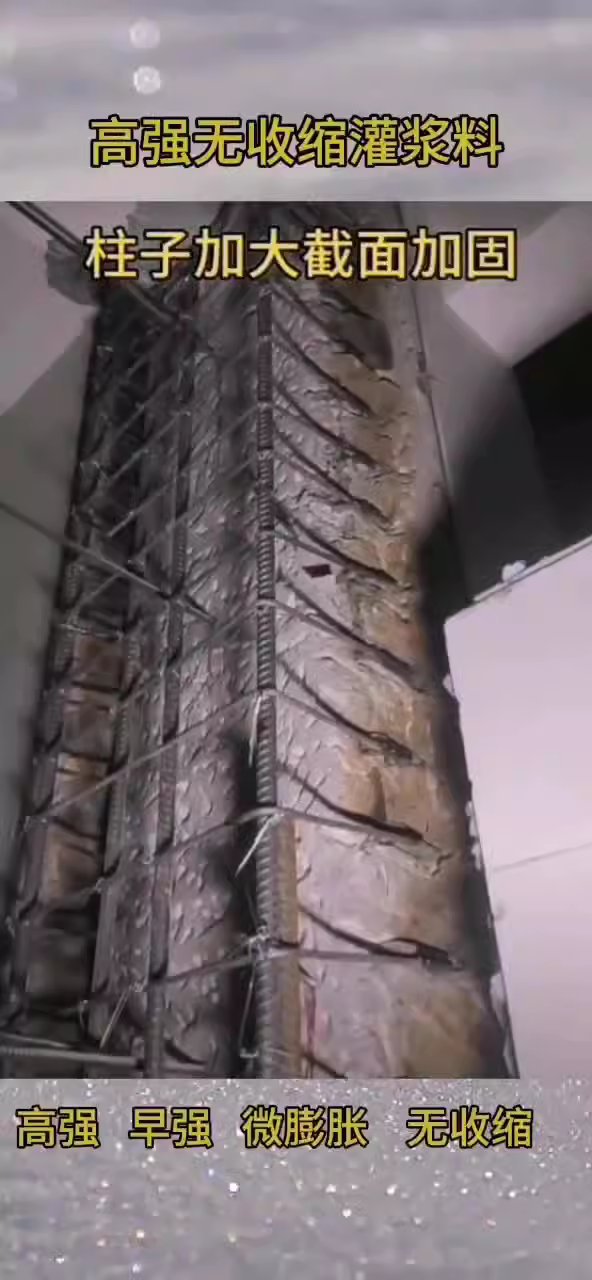

灌浆料主要用于:地脚螺栓锚固、飞机跑道的抢修、核电设备的固定、路桥工程的加固、机器底座、钢结构与地基怀口、设备基础的二次灌浆、栽埋钢筋、混凝土结构加固和改造、旧混凝土结构的裂缝治理,机电设备按装,轨道及钢结构安装,静力压桩工程封桩,墙体结构的加厚及漏渗水的修复,各种基础工程的塌陷灌浆以及各种抢修工程等。

|

型 号(Model)

|

抗压强度Compressive strength(MPa)

|

竖向膨胀率Vertical expansion rate(%)

|

流动度Fluidity

|

钢筋握裹强度Steel bar grip strength

(圆钢Round steel)/MPa |

泌水率Bleeding rate(%)

|

备注Remarks

|

||||

|

6h

|

1d

|

3d

|

28d

|

1d

|

初始流动度 Initial fluidity |

(30min)流动度保留值Flow retention value |

28d

|

|||

|

通用型(General-purpose)

|

--

|

≥15

|

≥30

|

≥70

|

≥0.02

|

≥260

|

≥230

|

≥4.0

|

≤1.0

|

|

|

高强型(High-strength type)

|

--

|

≥30

|

≥40

|

≥70

|

≥0.02

|

≥260

|

≥230

|

≥4.0

|

≤1.0

|

|

|

早强型(Early-strength type)

|

≥20

|

≥30

|

≥40

|

≥60

|

≥0.02

|

≥260

|

≥230

|

≥4.0

|

≤1.0

|

|

|

早强高强型(Early-strength and high-strength type)

|

≥22

|

≥30

|

≥40

|

≥70

|

≥0.02

|

≥260

|

--

|

≥4.0

|

≤1.0

|

|

|

超流态型(Superfluid state type)

|

--

|

≥15

|

≥25

|

≥50

|

≥0.025

|

≥300

|

≥250

|

≥3.5

|

≤1.0

|

|

|

耐高温型(High-temperature resistant type)

|

--

|

≥22

|

≥35

|

≥72

|

≥0.02

|

≥260

|

≥230

|

≥4.0

|

≤1.0

|

|

|

|

380

|

340

|

290

|

270

|

||

|

最大集粒径Maximum particle size(mm)

|

≤4.75

|

>4.75且≤16(>4.75 and ≤16)

|

||||

|

流动度Fluidity(mm)

|

初始流动值

|

≥380

|

≥340

|

≥290

|

≥270*

|

≥650**

|

|

30min保留值

|

≥340

|

≥310

|

≥260

|

≥240*

|

≥550**

|

|

|

竖向膨胀率Vertical expansion rate(%)

|

3h

|

0.1~3.5

|

||||

|

24h与3h的

膨胀值之差 |

0.02~0.5

|

|||||

|

抗压强度Compressive strength(Mpa)

|

1d

|

≥20

|

||||

|

2d

|

≥40

|

|||||

|

28d

|

≥60

|

|||||

|

对钢筋有无锈蚀作用Does it have a rusting effect on the steel bars

|

无(no)

|

|||||

|

沁水率Water infiltration rate(%)

|

0

|

|||||

工程设计参考Engineering Design reference:

地脚螺栓锚固用水泥基灌浆材料的选择Selection of cement-based grouting materials for anchor bolt anchoring:

|

螺栓表面与孔壁的净间距The clear distance between the surface of the bolt and the wall of the hole(mm)

|

水泥基灌浆材料类别Categories of cement-based grouting materials

|

|

15~50

|

340、290

|

|

50~100

|

290、270

|

|

>100

|

270

|

|

灌浆层厚度Thickness of the grouting layer(mm)

|

水泥基灌浆材料类别Categories of cement-based grouting materials

|

|

5~50

|

380

|

|

20~100

|

340

|

|

80~200

|

290

|

|

>200

|

270

|

四、产品特点

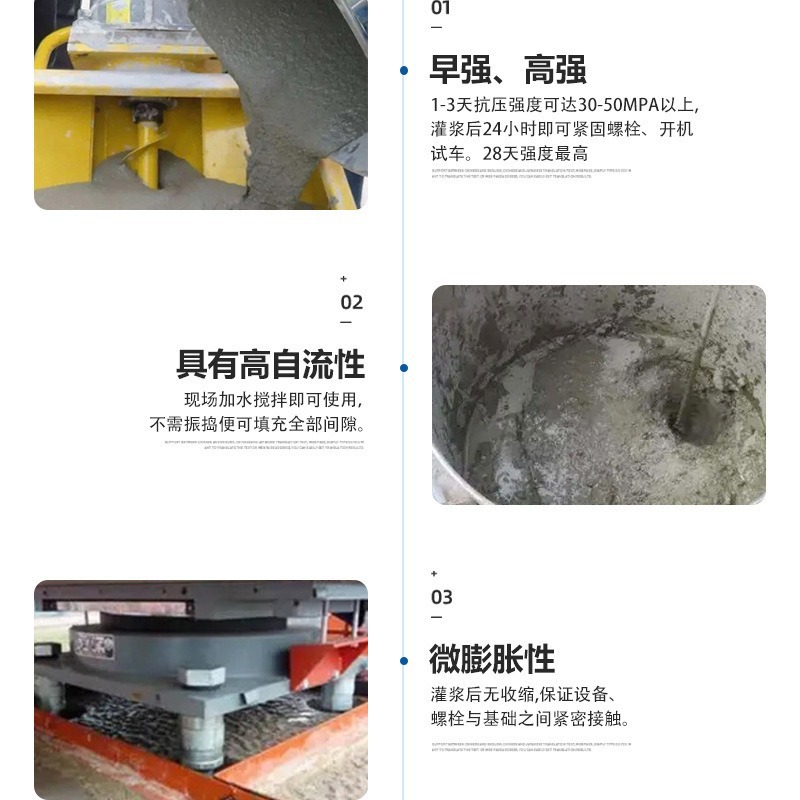

▲早强高强 浇后1-3天强度高达30Mpa以上,缩短工期(Early strength and high strength: The strength can reach over 30 mpa within 1 to 3 days after pouring, shortening the construction period.)。

▲自流态 现场只需加水搅拌,直接灌入设备基础,砂浆自流,施工免振,确保无振动、长距离的灌浆施工(The self-flowing state only requires water to be added and stirred on site, and then directly poured into the equipment foundation. The mortar flows by itself, and the construction is vibration-free, ensuring long-distance grouting construction without vibration)。

▲ 微膨胀 浇注体长期使用无收缩,保证设备与基础紧密接触,基础与基础之间无收缩,并适当的膨胀压应力确保设备长期安全运行(The micro-expansion castable has no shrinkage during long-term use, ensuring that the equipment is in close contact with the foundation, and there is no shrinkage between the foundations. The appropriate expansion compressive stress also guarantees the long-term safe operation of the equipment)。

▲ 抗油渗 在机油中浸泡30天后其强度提高10%以上,成型体、密实、抗渗、适应机座油污环保(After being soaked in engine oil for 30 days, its strength increases by more than 10%. The formed body is dense, impermeable, and environmentally friendly to oil stains on the machine base)。

▲ 耐久性 200万次疲劳试验,50次冻融环境试验强度无明显变化(After 2 million fatigue tests and 50 freeze-thaw environment tests, there was no significant change in strength)。

▲ 耐侯性好 -40℃~600℃长期安全使用(Good weather resistance, safe for long-term use at temperatures ranging from -40℃ to 600℃)。▲ 低碱耐蚀 严格控制原材料碱含量,适用于碱-集料反应有抑制要求的工程(Low-alkali corrosion resistance strictly controls the alkali content of raw materials and is suitable for projects where there is a requirement to inhibit alkali-aggregate reactions)。

五、使用方法Usage method:

1. 基础处理Basic processing

清扫设备基础表面,不得有碎石、浮浆、灰尘、油污和脱模剂等杂物。灌浆前24h,设备基础表面应充分湿润。灌浆前1h,应吸干积水(Clean the surface of the equipment foundation. There must be no debris such as crushed stones, floating slurry, dust, oil stains and mold release agents. Twenty-four hours before grouting, the surface of the equipment foundation should be fully moistened. One hour before grouting, the accumulated water should be sucked dry)。

2. 确定灌浆方式(Determine the grouting method):

根据设备机座的实际情况,选择相应的灌浆方式,由于具有很好的流动性能,一般情况下,用"自重法灌浆"即可,即将浆料直接自模板口灌入,完全依靠浆料自重自行流平并填充整个灌注空间;若灌注面积很大、结构特别复杂或空间很小而距离很远时,可采用"高位漏斗法灌浆"或"压力法灌浆"进行灌浆,以确保浆料能充分填充各个角落(According to the actual situation of the equipment base, select the corresponding grouting method. Due to its excellent flow performance, generally, the "self-weight grouting method" is sufficient, that is, the grouting material is directly injected from the formwork opening, and it completely relies on its own weight to level and fill the entire grouting space by itself. When the grouting area is large, the structure is particularly complex, or the space is small and the distance is long, "high-level funnel grouting" or "pressure grouting" can be adopted for grouting to ensure that the grouting material can fully fill every corner)。

3. 支模Formwork support

根据确定的灌浆方式和灌浆施工图支设模板,模板定位标高应高出设备底座上表面至少50mm,模板必须支设严密、稳固,以防松动、漏浆(According to the determined grouting method and grouting construction drawing, set up the formwork. The positioning elevation of the formwork should be at least 50mm higher than the upper surface of the equipment base. The formwork must be set up tightly and stably to prevent loosening and leakage of grouting)。

4. 灌浆料的搅拌Mixing of grouting material:

按产品合格证上推荐的水料比确定加水量,拌和用水应采用饮用水,水温以5~40℃为宜,可采用机械或人工搅拌。采用机械搅拌时,搅拌时间一般为1~2分钟。采用人工搅拌时,宜先加入2/3的用水量搅拌2分钟,其后加入剩余用水量继续搅拌至均匀,标准稠度加水量为12%-14%(The amount of water to be added should be determined according to the water-material ratio recommended on the product qualification certificate. The mixing water should be drinking water, and the water temperature is preferably between 5 and 40℃. Mechanical or manual stirring can be adopted. When mechanical stirring is adopted, the stirring time is generally 1 to 2 minutes. When manual stirring is adopted, it is advisable to first add two-thirds of the water volume and stir for 2 minutes. Then, add the remaining water volume and continue stirring until uniform. The standard consistency water addition is 12% to 14%)。

5. 灌浆Grouting:

灌浆施工时应符合下列要求(The following requirements should be met during grouting construction):

(1).浆料应从一侧灌入,直至另一侧溢出为止,以利于排出设备机座与混凝土基础之间的空气,使灌浆充实,不得从四侧同时进行灌浆(The slurry should be poured in from one side until it overflows from the other side to facilitate the expulsion of air between the equipment base and the concrete foundation, ensuring the grouting is complete. Grouting should not be carried out simultaneously from all four sides)。

(2).灌浆开始后,必须连续进行,不能间断,并应尽可能缩短灌浆时间(After grouting begins, it must be carried out continuously without interruption, and the grouting time should be shortened as much as possible)。

(3).在灌浆过程中不宜振捣,必要时可用竹板条等进行拉动导流(During the grouting process, vibration is not advisable. If necessary, bamboo strips or similar materials can be used to pull and guide the flow)。

(4).每次灌浆层厚度不宜超过100mm(The thickness of each grouting layer should not exceed 100mm)。

(5).较长设备或轨道基础的灌浆,应采用分段施工。每段长度以10m为宜(For grouting of longer equipment or track foundations, segmented construction should be adopted. The length of each section is preferably 10 meters)。

(6).灌浆过程中如发现表面有泌水现象,可布撒少量干料,吸干水份(If bleeding is found on the surface during the grouting process, a small amount of dry material can be scattered to absorb the moisture)。

(7)对灌浆层厚度大于1000mm大体积的设备基础灌浆时,可在搅拌灌浆料时按总量比1:1加入0.5mm石子,但需经试验确定其可灌性是否能达到要求(When grouting large-volume equipment foundations with a grouting layer thickness greater than 1000mm, 0.5mm of gravel can be added at a total ratio of 1:1 when stirring the grouting material, but it is necessary to determine through tests whether its grouting property can meet the requirements)。

(8).设备基础灌浆完毕后,要剔除的部分应在灌浆层终凝前进行处理(After the grouting of the equipment foundation is completed, the parts to be removed should be treated before the final setting of the grouting layer)。

(9).在灌浆施工过程中直至脱模前,应避免灌浆层受到振动和碰撞,以免损坏未结硬的灌浆层(During the grouting construction process until demolding, the grouting layer should be protected from vibration and impact to prevent damage to the unhardened grouting layer)。

(10)模板与设备底座的水平距离应控制在100mm左右,以利于灌浆施工(The horizontal distance between the formwork and the equipment base should be controlled at about 100mm to facilitate grouting construction)。

(11)灌浆中如出现跑浆现象,应及时处理(If grout leakage occurs during grouting, it should be dealt with promptly)。

(12)当设备基础灌浆量较大时,应采用机械搅拌方式,以保证灌浆施工(When the grouting volume of the equipment foundation is large, mechanical stirring should be adopted to ensure the grouting construction)。

6、养护Maintenance:

(1)灌浆完毕后30分钟内,应立即喷洒养护剂或覆盖塑料薄膜并加盖岩棉被等进行养护,或在灌浆层终凝后立即洒水保湿养护(Within 30 minutes after the grouting is completed, a curing agent should be immediately sprayed or plastic film should be covered and rock wool quilts should be added for curing, or water should be sprinkled for moisture retention curing immediately after the grouting layer has finally set)。

(2)冬季施工时,养护措施还应符合现行《钢筋混凝土工程施工验收规范》(GB50204)的有关规定(During winter construction, the curing measures should also comply with the relevant provisions of the current "Code for Acceptance of Construction of Reinforced Concrete Works" (GB50204))。

(3)在不同温度条件下的养护时间和拆模时间表(Curing time and formwork removal schedule under different temperature conditions)

日最低气温Daily minimum temperature(℃) 拆模时间Demolding time(h) 养护时间Curing time(d)

-10~0 96 14

0~5 72 10

5~15 48 7

≥15 24 7

网友评价 共0条 [查看全部]